Further to having a new inlet manifold for the super charger made I decided that I would review the work I had already done and undo some of the items I am not happy with and use this chance to get everything the way I want it.

As I had the inlet I decided to draw up the blower outlet and an adaptor for the bypass valve to fit the 2.5" pipe work. All this was CNC machined out of aluminium.

With the parts in my hands I set about making them all fit with the new charge cooler and pipework

I then sent all the parts out for powder coating just to keep it all looking as I want it

With the parts back I set about connecting everything back to the engine, I would like to say this was simple but I like to make my life difficult and there can be no other reason for all this faffing

I decided to relocate the mechanical coolant pump with a BMW piersburg electric pump. The pump is PWM controlled which is fine as I have a spare output on the Vipec. I made a mount so the pump goes where the AC mechanical pump used to fit and feeds the RH side of the engine as a cooper coolant pump would normally go.

The pump is very efficient and allows me to control it in different situations.

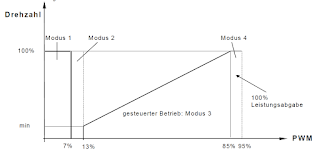

Here is the pump operation table

I am not sure why the table is reversed in the Vipec or I got it wrong but it all works. During tests I set the PWM table against the TPS so when I put my foot down the pump would kick in. It primes very quickly if you can get the coolant in the bottle fast enough.

The table I went with, you can see I decided to run my coolant temp vs engine speed but there are other variables running on the vipec which can over ride the PWM settings should something go wrong.

Lastly I made a new radiator as the last radiator was an ebay special and didn't quite offer enough cooling as it was to get it up and running to help me fault find

As I had the inlet I decided to draw up the blower outlet and an adaptor for the bypass valve to fit the 2.5" pipe work. All this was CNC machined out of aluminium.

With the parts in my hands I set about making them all fit with the new charge cooler and pipework

I then sent all the parts out for powder coating just to keep it all looking as I want it

With the parts back I set about connecting everything back to the engine, I would like to say this was simple but I like to make my life difficult and there can be no other reason for all this faffing

I decided to relocate the mechanical coolant pump with a BMW piersburg electric pump. The pump is PWM controlled which is fine as I have a spare output on the Vipec. I made a mount so the pump goes where the AC mechanical pump used to fit and feeds the RH side of the engine as a cooper coolant pump would normally go.

The pump is very efficient and allows me to control it in different situations.

Here is the pump operation table

I am not sure why the table is reversed in the Vipec or I got it wrong but it all works. During tests I set the PWM table against the TPS so when I put my foot down the pump would kick in. It primes very quickly if you can get the coolant in the bottle fast enough.

The table I went with, you can see I decided to run my coolant temp vs engine speed but there are other variables running on the vipec which can over ride the PWM settings should something go wrong.

You can see the coolant pump in the picture below, it uses a pump clamp which is welded on a AC delete bracket